our offering

More about our capabilities in wax blends and wax emulsions:

Unlock the value in our global sourcing and supply capabilities combined with our manufacturing presence and technical excellence to optimize your business.

Whether you need to secure your raw material stream, optimize your manufacturing process or consolidate your supply chain, we are able to help through our worldwide presence and expertise.

Paramelt is the largest independent global wax blender and has access to an enormous range of waxes and additives. Build on our extensive knowledge and capabilities, we develop just the right blend to meet your technical, commercial and manufacturing requirements.

Contact usIn addition to providing fully tailored wax solutions, we also work with a number of partners where our unique experience, material portfolio and process capability offers a value added contribution to their business through bespoke developments or tolling.

Rely on usour offering

More about our capabilities in wax blends and wax emulsions:

The world of wax includes an extremely broad range of wax types with different physical and chemical characteristics. Primary raw material sources only provide a finite product range within each family of specific waxes offering limited, well defined characteristics.

The formulator’s knowledge is key to translate these material features into the desired performance requirements. A large part of our activities are focused on using our knowledge and experience to select and blend components to supply functional and consistent grades of wax with targeted properties.

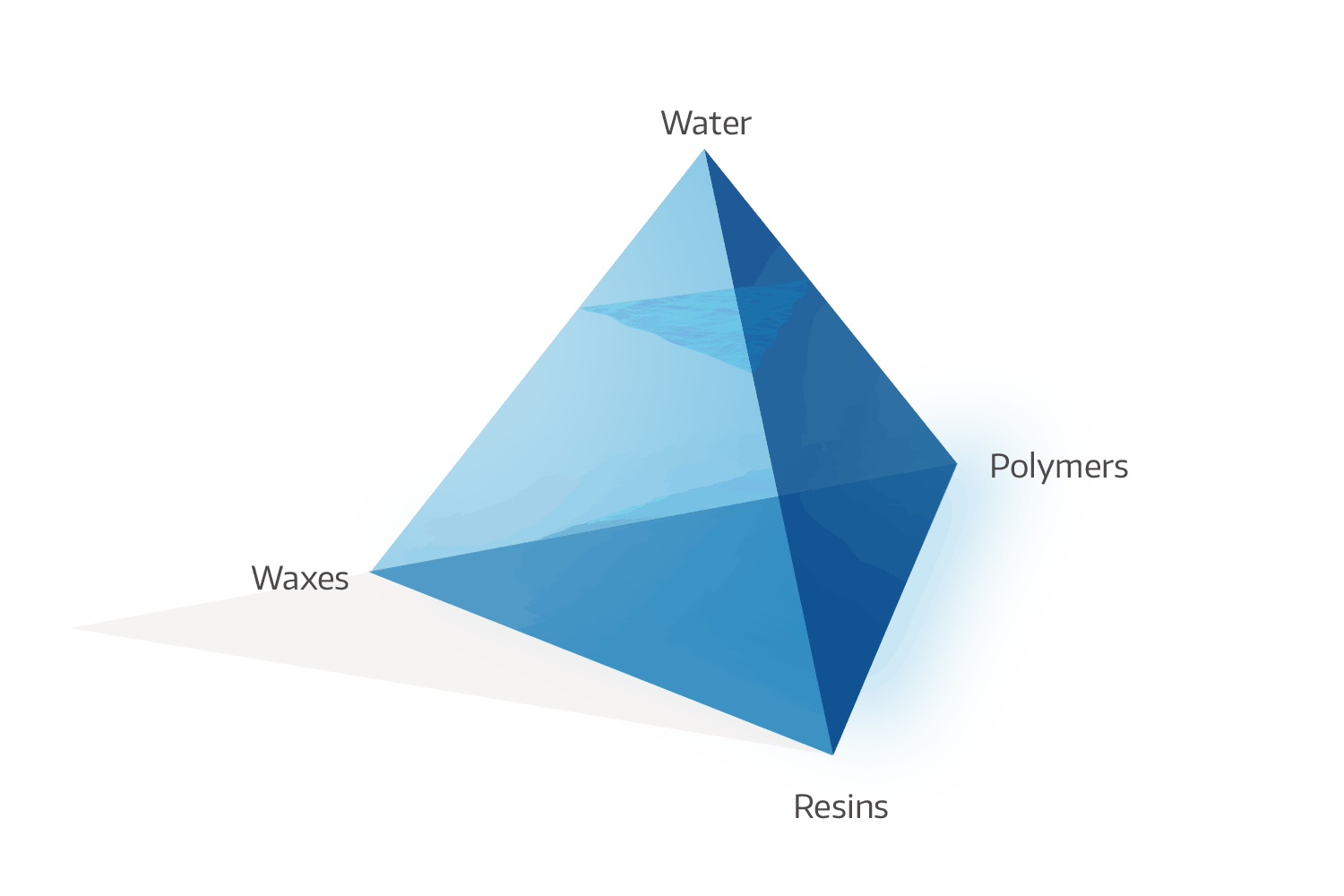

In addition, waxes are frequently combined with many different types of rosin and hydrocarbon based resins as well as olefinic polymers (e.g. EVA, PE, EMA) and other additives, such as stabilizers, fillers, pigments and dyes.

'this blending space represents the heart of Paramelt’s core business.'

We are able to select and combine the right balance of ingredients to consistently deliver the desired functionality, whilst also simplifying supply chain and manufacturing complexity for our customers. Buying pre-blended waxes from Paramelt brings our customers significant benefits to their business in aspects such as:

Many applications require the functionality of a wax into a water based formulation, such as water based flexible packaging coatings & inks, paints, lacquers and polishes, leather & textile treatments, fiber sizing agents, glass & ceramic bottle and jar treatments.

Paramelt has a comprehensive manufacturing capability for the production of wax emulsions and polymer dispersions, encompassing atmospheric and pressure emulsification, high-pressure homogenization, continuous mechanical dispersion and high shear mixing.

Through our activities in water based coatings and adhesives, we also have extensive mixing and blending facilities for water based systems, which enable us to incorporate our wax, and polymer, emulsions into formulated aqueous blends where required.

Although we are not strongly active in the mainstream wax emulsion market, we have developed and now supply an extensive range of wax emulsions to meet bespoke customer requirements. Within this range of products, we can offer anionic, cationic, nonionic and mixed surfactant systems across a broad range of wax families including:

Do you intend to focus on your core business and outsource part of your production? On a daily basis Paramelt has proven to many well known partners that contract manufacturing is a viable and reliable alternative. Want to know more about our approach and our capabilities in processing thermoplastic products?

Paramelt

Dutch, since 1898

revenue 2023: €263 mln

# employees 2023: 502

owned by Ter Group

Ter Group

German, since 1908

revenue 2023: €910 mln

# employees 2023: 1140

owned by Westphal family

Top 3 reasons to

recommend Paramelt*)

– reliable supplier

– consistent quality

– value for money

*) Customers survey Europe and USA

# active formulas

~2750

Annual re-investment rate

~10%

# laboratory requests

> 1000 last year

# new commercial products

~ 110 last year

Financial stability

D&B rating 1

manufacturing sites

Europe : 3

USA : 3

China : 2

customers in

87 countries

Average employee retention

> 12 years

Paramelt = ‘knowledge & experience’

recognized by > 85% customers

(Customers survey Europe and USA)

With 8 production facilities delivering in more than 80 countries, we have truly global perspective and local service.