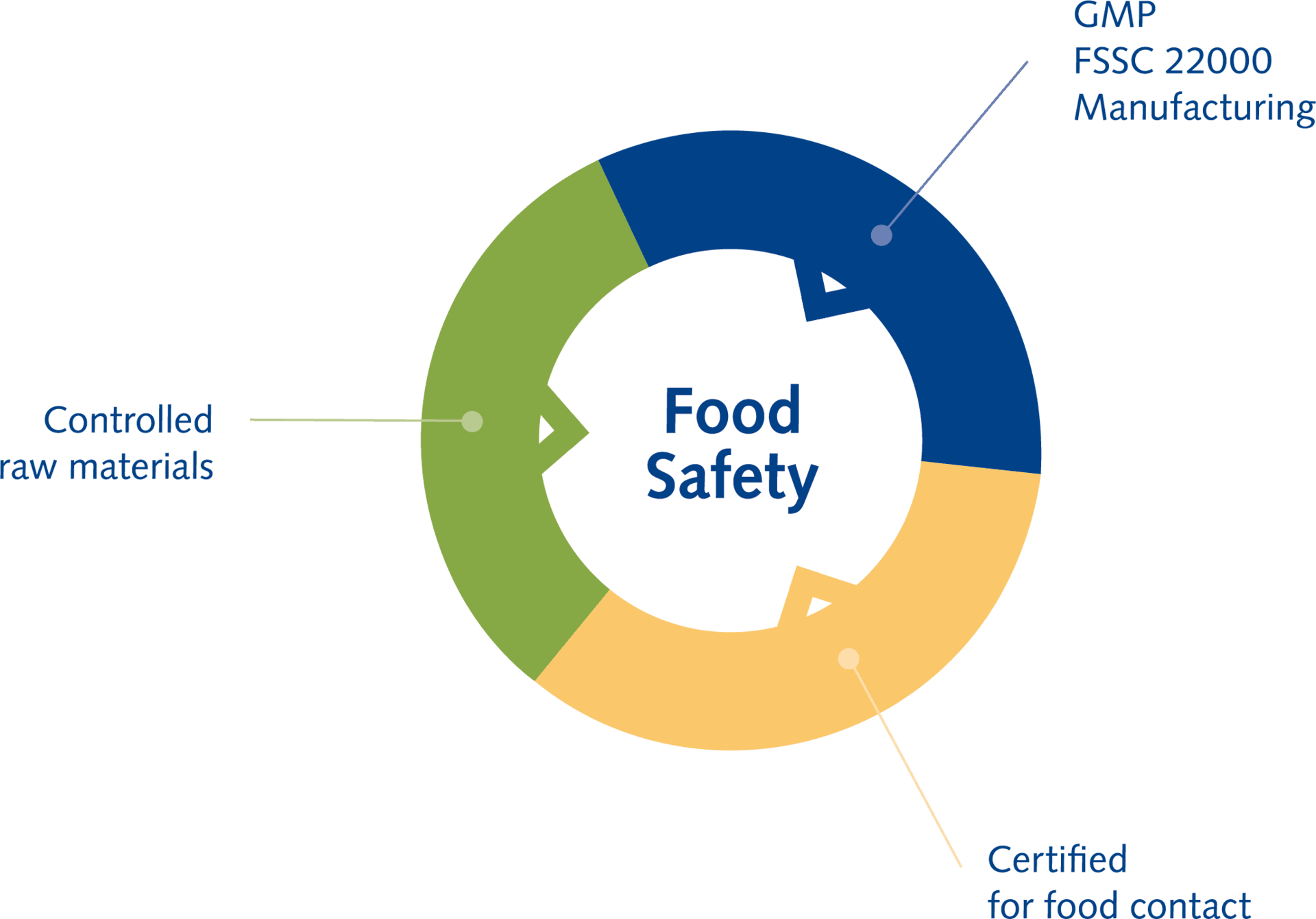

Food safe production

FSSC 22000 certified facilities

Paramelt is involved in a number of critical industries where consumer safety is of utmost importance.

Our Paracera range for cosmetics & personal care, Paraflex products for direct food contact packaging as well as waxes used as food ingredients and our Paradip waxes for cheese coating all require their own specific, stringent manufacturing criteria in order to meet the necessary regulatory standards. Even for ‘end of line’ packaging hot melts, such as our Excelta and Plastomelt grades, food producers have ever increasing expectations for their regulatory compliance and food safety status.

As a result of these demanding product requirements, we have invested heavily in our operating facilities and procedures, using comprehensive standards of HACCP and GMP to achieve market leading levels.

To validate the suitability of these processes and take advantage of industry best practice, Paramelt have taken the step to go beyond general compliance with GMP and ISO 9001 to certify a number of their facilities to an internationally accredited standard. Whilst many standards, such as AIB and BRC are common in the food industry, the decision was taken to certify to the most demanding and globally recognised FSSC 22000 standard to ensure the widest possible acceptance across the diverse range of industries we serve.

What is FSSC 22000

The FSSC 22000 Food Safety System Certification provides a comprehensive framework for effectively managing an organization’s food safety responsibilities. The approach is built on existing ISO standards and is fully recognized by the Global Food Safety Initiative (GFSI).